ISOVOLT Lynx stationary X-ray machine

The ISOVOLT Lynx is the first in a new generation of stationary X-ray machines from Inspection Technologies.

It represents a major advance in X-ray generator technology, incorporating the latest electronics and digital concepts to allow greater performance and reliability.

It has been designed to align with the optimized performance of other components in the X-ray inspection imaging chain for a wide range of applications including the automotive, aerospace and metals manufacturing sectors, for tasks such as the inspection of welds, composites and castings, as well as in 3D computed tomography and metrology.

It will be of particular interest to system integrators working in both the industrial and scienti?c sectors.

ISOVOLT Lynx Generator

GE introduces the next generation of stationary X-ray machines with the new ISOVOLT Lynx, which is one of the most signi?cant innovations in X-ray generation for the past 10 years.

There have been enormous strides in imaging and tube technology over the past decade but the generator technology has been pretty static. By leveraging many of the concepts employed in the GE healthcare business, using their latest state-of-the-art technology, we have been able to develop this new industrialized version for industrial customers.

This development has required us to create an application map for each potential generator application and then de?ne the generator specifications needed to meet and optimize the tube, imaging and inspection standard requirements for that application.

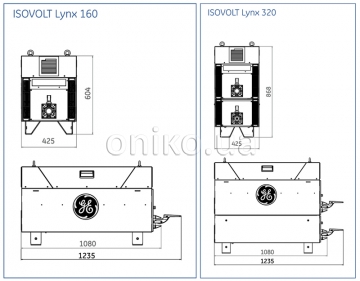

The result is a flexible and versatile generator platform which offers high reliability and performance across a very broad application spectrum. It is also a very scalable platform, which will allow us to meet future integration and monitoring requirements and the needs for higher energies, even up to 600 kV. In a first stage the ISOVOLT Lynx will be available as 160 kV and 320 kV version.

Both generators offer enhanced maintenance free options: maintenance free high voltage plugs on the generator side and new maintenance free bipolar tube housing for the 320 kV version. The integration into fully automated systems for in-line operation has also been optimized. The optional ISOVOLT Lynx Remote Control or the ISOVOLT Lynx Control ensure a simple configuration, control and operation.

| Reliability | Performance | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||

| Safety & Compliance | Ease of Integration | ||||||||||||||||||||||

|

|

||||||||||||||||||||||

| Serviceability | Diagnostics | ||||||||||||||||||||||

|

|

||||||||||||||||||||||

| Cost of Ownership | Flexibility | ||||||||||||||||||||||

|

|

ISOVOLT Lynx Control

A user-friendly, multi-language control features a clear full-colour graphical display with touch screen, that allows simultaneous readings of set and actual operating parameters. Embedded in an ergonomic and rugged desktop or optional 19” rack mounting housing, full control of X-ray operation features, service and system configuration features, online monitoring of relevant system parameters is established. Intuitive guidance through diverse menus as well as unmistakable messages for clear interventions are provided with this module.

A user-friendly, multi-language control features a clear full-colour graphical display with touch screen, that allows simultaneous readings of set and actual operating parameters. Embedded in an ergonomic and rugged desktop or optional 19” rack mounting housing, full control of X-ray operation features, service and system configuration features, online monitoring of relevant system parameters is established. Intuitive guidance through diverse menus as well as unmistakable messages for clear interventions are provided with this module.

Features such as free configurable exposure programs, or special programs for constant power, constant current and manual operation cater for individual demands for radiographic or radioscopic inspections. The multi-lingual user display with 16 different languages and extended character sets for Japanese, Cyrillic and Chinese enables comprehensible and simple interaction.

ISOVOLT Lynx provides automatic and manual warm-up modes for optimized tube conditioning. A special extended warm-up mode safeguards tube performance under severe conditions and setups.

ISOVOLT Lynx Remote Control

Designed for the needs of system integrators this PC based tool provides full control over all ISOVOLT Lynx operation, service and diagnostics features.

Designed for the needs of system integrators this PC based tool provides full control over all ISOVOLT Lynx operation, service and diagnostics features.

It can be installed on every WIN 7 or WIN XP PC and can be connected via a USB/RS-232 cable with the ISOVOLT Lynx generator.

Alongside with the optional fail-safe E-Stop Control Box, ISOVOLT Lynx Remote Control establishes a full PC based generator control and management platform.

X-ray Tubes

ISOVOLT Lynx supports a comprehensive portfolio of monopolar and bipolar X-ray tubes from different suppliers.

Please contact your sales representative for consultation on X-ray tube selection.

Technical Specifications

ISOVOLT Lynx 160 |

ISOVOLT Lynx 320 | |

|---|---|---|

High Voltage Generator |

||

| Performance | ||

| Max. Output Voltage | 160 kV | 320 kV |

| Tube Voltage | from 25 kV to 160 kV | from 50 kV to 320 kV |

| Max. Output Current | 45 mA | 45 mA* |

| Tube Current | 1 mA - 45 mA* | 1 mA - 45 mA* |

| Max. Output Power | 4 kW** | 4.5 kW** |

| Resolution (Voltage / Current) | 0.1 kV / 0.01 mA | 0.1 kV / 0.01 mA |

| Absolute Accuracy (Voltage / Current) | ±1,5% / < 1% | ±1,5 % / < 1% |

| Stability (Voltage / Current) | < 0,01% / < 0,01% *** | < 0,01% / < 0,01% *** |

| Insulation | Oil (sealed high voltage tank) | Oil (sealed high voltage tank) |

| Interfaces | ||

| High Voltage Connections | R24 Quick Release Flat Socket maintenance free (optional) |

R24 Quick Release Flat Socket maintenance free (optional) |

| Signal | Door contacts, interlock,external E-stop, additional potential-free contacts, standard connections for warning lamp, warning light and cooler/chiller | Door contacts, interlock,external E-stop, additional potential-free contacts, standard connections for warning lamp, warning light and cooler/chiller |

| Data | RS-232 USB Ethernet |

RS-232 USB Ethernet |

| Dimensions | ||

| Dimensions (W x D x H | 1080 x 425 x 605 mm (42,52” x 17,7” x 23,82”) | 1080 x 425 x 870 mm (42,52” x 17,7” x 34,25”) |

| Âåñ | 120 kg (265 lb) | 200 kg (441 lb) |

| Electrical Connection | ||

| Mains | 1N PE 230V ±10%, 50/60 Hz | 1N PE 230 V ±10%, 50/60 Hz |

| Installation Conditions | TN-S or TN-C according EN 32 / UL 35, power requirement 6,7 kVA, cos Phi = 0.9-1.0 | TN-S or TN-C according EN 32 / UL 35, power requirement 6,7 kVA, cos Phi = 0.9-1.0 |

| Environmental | ||

| Operating Temperature Range | 0°C to +40°C | 0°C to +40°C |

| Storage Temperature Range | -30°C to +70°C | -30°C to +70°C |

| Certification | ||

| Certification | CE, UL, NFC 74 100 | CE, UL, NFC 74 100 |

|

||

Control Module |

||

| Features | Touch-resistive, color display Desk-top housing X-ray on/off, E-Stop, 3-position key switch |

|

| Dimensions | 390 x 240 x 120 mm (15,35” x 9,45” x 4,72”) | |

| Weight | 1.2 kg (2.64 lb) | |

Remote Control |

||

| Features | PC application X-ray control and service (Win 7, Win XP) USB to RS232 converter Fail-Safe E-Stop Box (optional) |

|

| * 40 mA permanent operation, limited to peak operation ** Limited to tube specification, temperature and operating mode *** At constant temperature level |

||