Mentor EM Eddy Current Flaw Detector

Mentor EM Eddy Current Flaw Detector

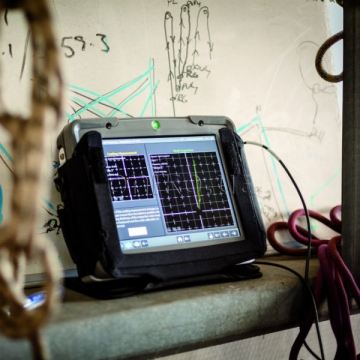

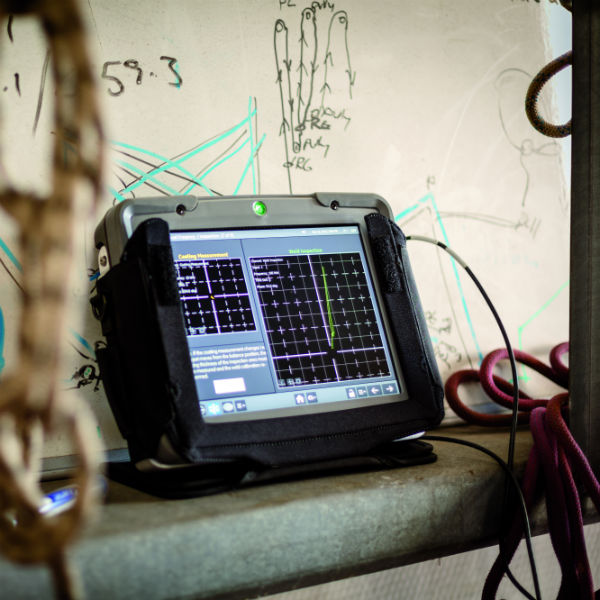

GE Mentor EM allows you to easily access on-device workflow applications that efficiently and accurately capture electromagnetic inspection data. Put expertise right in your hands.

Innovative Design

The all-new GE Mentor EM redefines eddy current inspection with its excellent signal-to-noise ratio and high-resolution display that’s easy to see in any light. It incorporates user-designed-application workflows, and onboard Wi-Fi capability so that inspectors of all levels can easily communicate with each other. Plus an off-the-shelf lithium-ion battery with battery energy content of less than 100Wh, means you can easily transport the Mentor EM on aircraft and helicopter.

Instant Collaboration

It’s not just about getting readings, it’s about getting accurate readings, every time, from every inspector. With Mentor EM, NDT experts connect wirelessly to their inspectors in the field to review real-time inspection results and support them as they gather data. They can even share screens instantly and add notes or comments in real time. Training is easy and inspectors can share screens to troubleshoot on the spot. No more hard copy service bulletins or chance of miscommunication. Everything they need will be right there in their hands—in real time.

A New Approach

Use Mentor EM to tailor on-device workflow applications that help your business run more smoothly and efficiently. Ensure everyone is following the exact same procedures, decrease the learning curve, and improve the consistency of testing by developing your own workflows for every test. The Mentor EM with Mentor Create—a new level of inspection technology.

Weld Solutions

With three preloaded application workfl ows, inspectors can select single, dual or dynamic gain control inspections for simultaneous crack detection and coating thickness measurements.

- Ready for the harshest environments with a superior IP rating

- Multiple alarm gates for tracking multiple defects

- Bluetooth and Wi-Fi enabled for easy connectivity to accessories and people

Aerospace (Including Rotary) Solutions

View Timebase and Spot perspectives at the same time to detect both radial defect positioning and sizing.

- High torque for fastener hole scanning

- Excellent signal-to-noise ratio for improved accuracy

- Fully customizable to each inspector’s personal preferences

General Purpose Solutions

With Bluetooth and Wi-Fi data transmission, collaboration can happen remotely—whether you’re on the tarmac inspecting landing gear, hanging off an offshore platform inspecting welds or checking automotive bearings in a production line.

- Superior signal-to-noise ratio for an incredibly clean and sharp signal

- Easy-to-read high-resolution display for visibility in tough conditions

- Downloadable on-device workfl ow applications for fast and consistent inspections

The Future of Mentor EM

Exciting things to come. From innovative technology to increased connectivity, GE’s Mentor EM is helping people make smarter decisions. A new online library will contain downloadable workfl ows to help everyone access the most up-to-date workfl ows and get the most out of their devices. And NDT experts all over the world will be able to share their expertise and inspection procedure workfl ows with one another.

Mentor EM is equipped for use with future applications such as:

- Heat exchanger, condenser, HVAC and ID tube inspection

- High POD pencil probes for increased speed of inspection without losing sensitivity

- Arrays for large area surface scanning

- Customized small systems integration for automated inspections