Quality Assurance Tools

To assist our customers in making sure the film systems render the expected capability in daily use, we refer to the standards for radiographic examination. EN444, ISO 5579, ASTM E94 and others specify that the user has to process the films in accordance with the conditions recommended by the manufacturer and pay special attention to monitor and control developing, fixing and washing. ASTM E94 states: “To produce a satisfactory radiograph, the care used in making the exposure must be followed by equal care in processing. The most careful radiographic techniques can be nullified by incorrect or improper darkroom procedures.”

Therefore, EN 584 and ISO 11699 consist of two parts. EN 584-2 and ISO 11699-2 describe how the user should control his or her processing system. For instance, to guarantee the designed film system’s performance, calibrated pre-exposed strips provided by the film manufacturer must be used.

We designed the Structurix Quality Assurance Tools, a set of practical, dedicated tools for the radiographer to control and prove compliance of his or her entire system.

Structurix Certified PMC Strip (Process Monitoring Control)

The Structurix Certified PMC strip is a handy, fast and reliable tool for monitoring the quality of the film processing system and for proving compliance with existing standards on systems classifications.

X-ray pre-exposed film strips

These X-ray pre-exposed film strips are produced under Agfa’s Quality Management System (Q.M.S) conditions according to ISO 9001-2000.

Contents

Every Structurix Certified PMC pack contains:

- 25 X-ray exposed, undeveloped PMC strips in individual daylight packaging. Each strip bears a unique serial (ID) number, even after processing

- A PMC chart to record test results showing compliance with the standards

- Detailed instructions for use

- A certificate for compliance with EN 584-2 and ISO 11699-2

Purpose

- Demonstrate conformity with the certified Structurix standard film system, as defined in European standard EN 584 part 2 and ISO 11699-2

- Monitor the performance of the Structurix processing system, in order to guarantee consistent high quality

- Enable early corrective actions to be taken in case of deviations

- Be used on a day to day basis to provide control data as part of a quality management system (e.g. ISO 9001- 2000)

Structurix Certified DENSTEP

The Structurix CERTIFIED DENSTEP is a density step wedge film to verify the calibration of optical transmission densitometers used in the industrial X-ray field.

Each Structurix CERTIFIED DENSTEP is:

- Packed in a light-tight waterproof package which protects it against moisture, dust, etc. guaranteeing a shelf life of at least four years

- Provided with a calibration certificate and a copy of the NIST certificate S.R.M. 1001

The density values reported, cross referenced by serial number to the certificate, are traceable to NIST (the United States National Institute of Standards and Technology) through traceable calibrations of the instrumentation and procedures in accordance with our ISO 9001-2000 approved QA system.

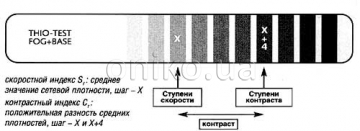

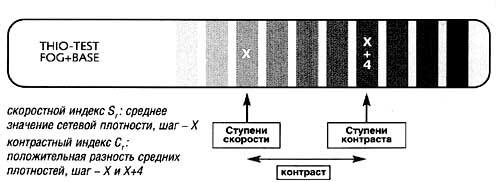

Structurix THIO-Test

Archivability Check

The archivability of the processed film is evaluated by measuring the residual thiosulphate in the emulsion layers. The Structurix Thio-Test provides the means for performing the control of fixing and washing as described in EN 584-2 and ISO 11699-2.

The Structurix Thio-Test kit consists of:

- Thio-Test Color Stepwedge with four steps, which relate to the archivability expressed in number of years

- One dropper bottle of Thio-Test reagent, of 35 ml (about 1,000 drops)

The Structurix Thio-Test also correlates perfectly with other international standards (ISO/ ANSI) for determining the archival quality of industrial X-ray film. It is a quick and simple method to determine the “life expectancy” of processed films and warns of poorly fixed and/or washed films.