Chlorine Dioxide Generators CAPITAL CONTROLS® T70G4000

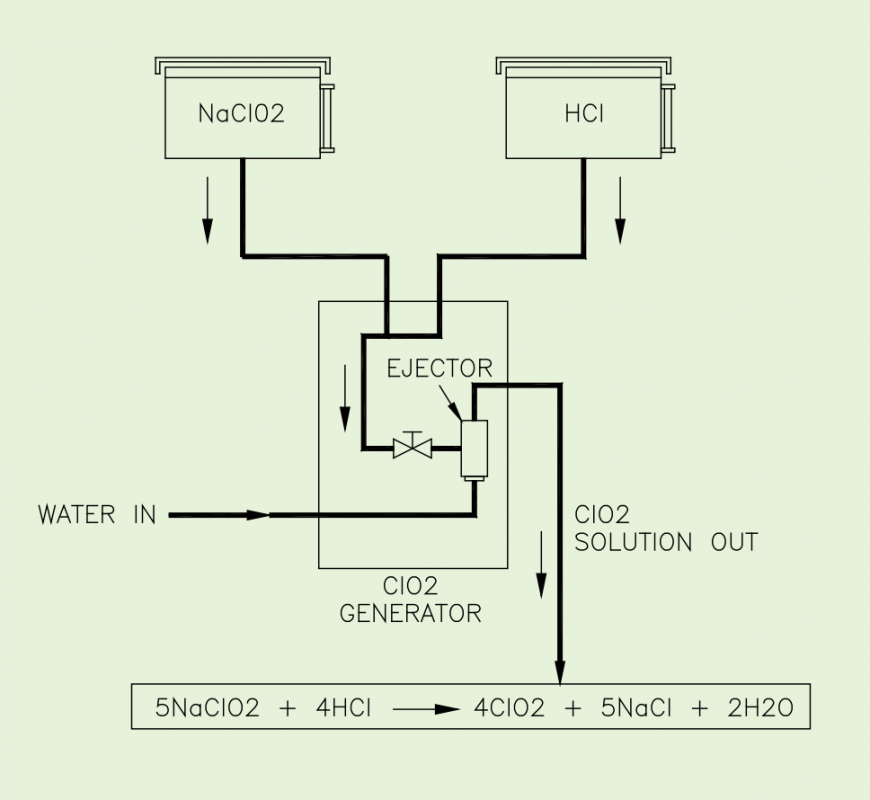

The Model T70G4000 chlorine dioxide generator is designed to produce and consistently maintain a product yield greater than 90%, which makes it ideal for drinking water treatment. It is a two-chemical system, utilizing commercially available concentrations of hydrochloric acid and sodium chlorite in the production of chlorine dioxide. No chlorine gas is required. A proven design, durable construction and the use of the best available corrosion-resistant materials assure efficient gas production, precise solution feeding, low maintenance and dependable operation for the life of the equipment.

The Model T70G4000 chlorine dioxide generator is an all-liquid system. Research has shown a market trend towards chlorine dioxide generators that do not require chlorine gas for the production of chlorine dioxide. This system is designed for use with 8,5% or 32% hydrochloric acid and 7,5% or 25% sodium chlorite. These are commercially available concentrations, eliminating the need for cumbersome dilution systems and softened water.

The Model T70G4000 chlorine dioxide generator is an all-vacuum system, preventing the escape of chlorine dioxide gas to the atmosphere. The reagents are drawn into the generator by a vacuum, produced by an integral ejector. The chlorine dioxide gas produced by the generator is mixed with the ejector motive water and applied as a solution to the treatment process. The Model T70G4000 chlorine dioxide generator is available for either manual or automatic control. Chlorine dioxide gas production can be manually controlled by manual rate valves located on the cabinet face or automatically controlled by a Chloromatic™ valve, which accepts a 4-20 mAdc input control signal from a flow transmitter or a residual controller.

DESIGN FEATURES:

– High Yield: Generator has been designed to produce and consistently maintain a product yield greater than 90%.

– All Liquid System: 8,5% or 32% Hydrochloric acid and 7,5% or 25% sodium chlorite are the reagents used to generate chlorine dioxide. No chlorine gas is required.

– All Vacuum System: The reagents are drawn into the generator by a vacuum, produced by an integral ejector. The chlorine dioxide gas produced by the generator is mixed with the ejector motive water and applied as a solution.

– Manual or Automatic Control Options

– Safe Operation: An all-vacuum system prevents escape of gas to atmosphere and provides fail safe shut-down with loss of vacuum.

– Minimum Maintenance: Corrosion-resistant materials;

All periodic maintenance items are easily replaceable.

CAPACITIES:

Standard chlorine dioxide generators units are available in the following power ratings:

80, 150, 300, 500, 1000, 2000, 4000, 6000, 8000, 10000 g / h of gaseous chlorine dioxide - when using high concentration reagents;

80, 150 and 300 g / h of gaseous chlorine dioxide - when using reagents of low concentration.

SAFETY FEATURES:

If a low vacuum condition exists, a valve will shut-off reagent flow to the generator. A vacuum regulating valve prevents both overpressure and excessive vacuum conditions. An optional flow vacuum switch is available for remote alarm indication. Each reagent flowmeter includes a detector with alarm, which detects the presence/absence of reagent with contacts available for alarm transmission.