Fixer G 334. G334 is Agfa's standard two-part universal fixer.

G334 excels by a lower emission of process-specific odors. This has been achieved by reducing the emission of both acetic acid and sulphur dioxide. The power and the accuracy of the fixer have not diminished and you will not, therefore, need to increase the replenishment rates of the processor.

G334 is Agfa's standard two-part universal fixer.

Can be used with following products and services

G334 fixer has been designed to be used in combination with G138i or G139 developer.

Flexible and universal

G334 is suitable for use in automatic processors and will allow you to process a wide variety of X-ray films such as CURIXTM, SCOPIXTM and MAMORAYTM films. G334 fixer has been designed to be used in combination with G138i or G139 developer.

Reduced emission of chemical substances

The majority of chemical substances used in common developers and non-hardening fixers dissolve readily in water and do not excessively evaporate into the air. G334 fixer, however, contains an acetic acid pH buffer and sodium sulphite to prevent the fixing salt in the fixer from decomposing. The emission of both acetic acid and sulphur dioxide using G334 has been greatly reduced.

E.O.S. technology compatible

G334 is also suitable for on-line silver recovery. In combination with the Ecologically Optimized System (E.O.S.) it is possible to obtain a minimal replenishment rate. Ecologically improved packaging

Ecologically improved packaging

The G334 fixer is supplied in shipping cartons manufactured using 60 % recycled cardboard. The cartons have been provided with two handles for easy tilting and transportation. Each carton contains two two-part kits, each sufficient for preparing 25 liters (G334) or 20 liters (G334) of ready-to-use solution.

Parts A and B are packed in translucent polyethylene (PE) bottles fitted with PE ECO seals. The screw cap and the stripe at the top of the label are color-coded for identification purposes (blue for fixer). The colored components, however, have been reduced as much as possible and the bottles show no aluminium remnants after use. Both features make the bottles easily PE-recyclable.

Easy bottle handling

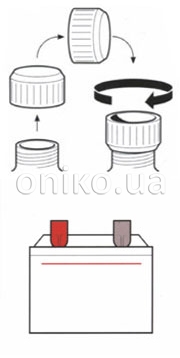

You can easily open the bottles using the built-in cutting edges of the cap. Simply open the cap, place it upside down on the bottle, apply a little pressure and turn the cap clockwise to break the ECO seal.

Easy automatic mixing

You can easily mix the parts using the automatic mixing units. Remove the cap, invert the bottle with the ECO seal over the seal opener and press. The seal is automatically broken and the contents can flow into the tank on the mixing unit. Whatever the mixing procedure, automatic or manual, mixing will never result in sludge formation.

More information here ...