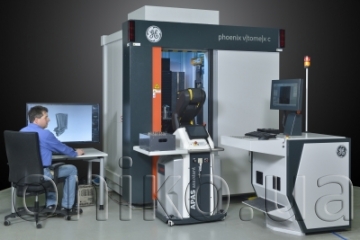

phoenix v|tome|x c

Our phoenix v|tome|x c inspection solution offers a compact 450 kV CT system specially designed for non-destructive testing (NDT) and quality assurance labs in foundries or aerospace applications allowing combined semi-automated non-destructive testing and 3D metrology. The low maintenance and production-oriented design features like easy loading tools, barcode reader etc., as well as the new one-button|CT automation functionality make the system a very efficient tool for high throughput industrial quality assurance.

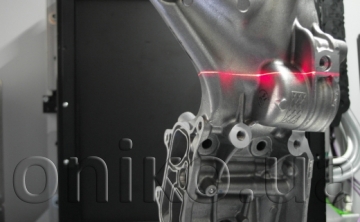

It is the first industrial minifocus CT scanner with Waygate Technologies proprietary breakthrough scatter|correct technology option allowing users to gain a low scatter artifact CT quality level never before reached with conventional industrial flat panel cone beam CT. Waygate Technologies new scatter|correct technology automatically removes most scatter artifacts from the CT volume. This technological advancement provides image quality similar to that achieved with conventional fan beam scanning but at speeds up to 100 times faster.

The quick|pick manipulator of the high speed configuration HS even allows fully automated CT evaluation of large batches, e.g. to scan up to 25 turbine blades without any operator action within approx. 2 hrs. The system offers industry leading sample size, flexibility and maximum penetration power for high absorbing samples at 450 kV.

Key Features

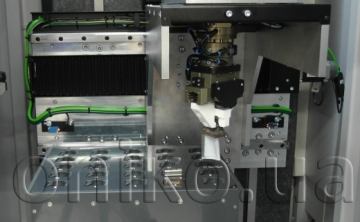

- Industry-leading detector performance

The phoenix v|tome|x c comes standard with our exclusive 4 MP dynamic 41|200 next generation photodiode design industrial X-ray detector, It provides 10x increased sensitivity relative to state of the art 200µm pixel size DXR detectors producing 2-3x cycle time increase without image quality impact, making inspections and measurements more efficient and productive.

As an premium option, the 100µm / 16 MP dynamic 41|100 detector provides 2x resolution increase without cycle time impact. Detection of 2x smaller defects without increase of geometric magnification allows imaging of large objects at higher resolution.

- Precision metrology, flexible operations

CT scanning provides precise 3D coordinate information of visible and non-visible surfaces. The phoenix v|tome|x c delivers a measuring precision of 20+L/100 µm relative to the VDI 2630 guideline.

The phoenix v|tome|x c can inspect different parts from multiple production lines for statistical production process control in one pass and completed as quickly as possible.

-

High throughput, automated CT process

Advanced scatter|correct technology enables scanning up to 100 times faster compared to similar precise state of the art fan beam CT, without compromising image quality—even for high-scattering materials or composite samples. The dynamic 41 digital detector can double scan speed or resolution.

With one-button|CT functionality, the entire CT scanning process can be fully automated, minimizing operator time. In the high-speed (HS) configuration, the quick|pick manipulator allows for fully automated blade inspection.

The phoenix v|tome|x c boasts a robust, small footprint for production control with a low cost of ownership.

- Increased flexibility and productivity

Inspect different parts from different production lines for statistical production process control in one go, as quickly as possible.

- Reproducible 3D Metrology

Besides inspection, CT scanning also provides precise 3D coordinate information even of hidden surfaces. The phoenix v|tome|x c delivers a measuring precision of 20+L/100 µm referring to VDI 2630 guideline.

- Optimized production process

Get industrial-strength CT performance specified referring to ASTM E 1695 guideline without the high cost of maintenance and operator time, while increasing sample size, flexibility, and penetration power for high-absorbing samples.