HWSL 3775 Magnetic Particle Flaw Detection

HWSL 3775 MAGNETISING FIXTURE Designed to process Disc/Ring type components without making contact.

The HWSL unit is designed to process disc type components with a maximum diameter of 610 mm, a minimum bore of 30 mm and a maximum thickness of 240 mm.

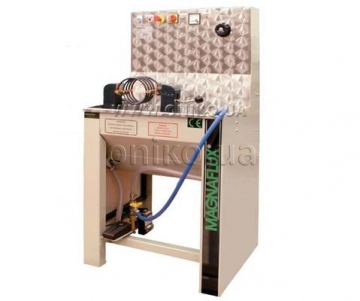

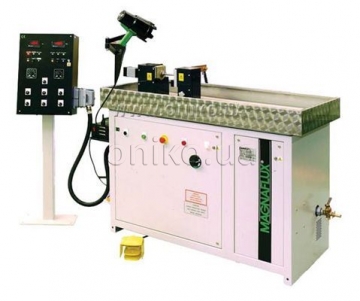

The unit consists of a welded framework designed to be attached to a mobile drain tray. Sitting in this framework is a 660mm diameter spiral coil, which in turn sits in a 750mm square stainless steel drain tray. Magnetic Ink is applied to the component from the MAGNAFLUX Bench Unit or by aerosol/pressure spray unit, etc. and will collect in the drain tray. Passing through the centre of the spiral coil and making contact with a pad positioned below is a 25mm diameter insulated copper central conductor. The upper end of this conductor is held by a pneumatic clamp. The whole assembly being mounted on castors.

The spiral coil and central conductor will have flying leads of 108mm2 cable fitted with eitherend connectors. These will either plug into the MAGNAFLUX Power Pack or to eitherend connectors fitted on a contact block # 023A007. This block is clamped between the head and tailstock of the MAGNAFLUX Magnetic Bench. The current may be applied to either the spiral coil or central conductor by changing over the pairs of cables, and current level is controlled from the Power Pack or Bench Unit. Power to the solenoid controlling the central conductor clamp is achieved by plugging the wander lead into the auxiliary socket on the Power Pack or Magnetic Bench.

Specification and Operating Data

Overall Length: 800 mm

Overall Height: 1500 mm

Overall Depth: 900 mm

Height to Working Surface: 1000 mm

Air Supply to Regulator: 4 bar

Maximum Component Weight: 100 Kg

Maximum Component Diameter: 610 mm

Maximum Component Height (for clamping threader bar): 240 mm

Unit Colour: RAL 7032

More information here ...