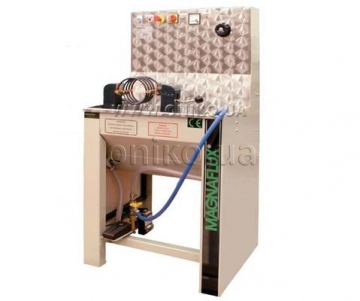

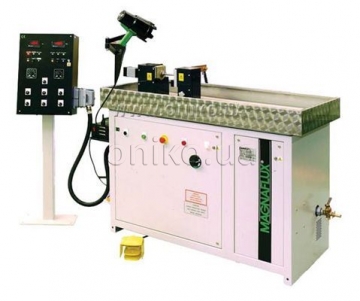

MD3-2060 Magnetic Particle Flaw Detection

The MD3-2060 is our most versatile, powerful standard multidirectional unit. It offers timesaving multidirectional magnetization for detecting defects in all directions with one cycle, or conventional two-cycle operation. It provides alternating current (AC), full wave DC (FWDC), and half wave DC (HWDC) magnetization for surface or near-surface flaws. It provides enough amperage for a wide range of parts. A programmable logic controller (PLC) and a user-friendly graphical operator interface accomplish superior control of the units operation.

Benefits

- Ensures Cycle Repeatability by Controlling Mag Shots and Bath Applications

- Security System (password protection, supervisor locks) reduces the risk of error in set up and inspection by ensuring proper amperage fields

- 50 Customer Programmable menus for pre-programming of inspection setups. (Parameters for Magnetization/ Demag)

- Automatic Piece Parts counter for quality control reporting

- Quick Disconnect Wiring installed for ease of serviceability

- Decaying AC and Reversing DC Demagnetization to help reduce gauss level in part and enhance post operations like drilling, grinding, welding

- Controlled Break Circuitry/Quick Break which ensures magnetic field wraps around ends of test piece (crucial to final inspection)

- Current Assurance Indicator lets operator know the current did not pass thru or magnetic field was not set up in test piece

- Front & Hardwood Grilles: impervious to oils & water, forgiving surface for parts that may be accidentally dropped

- Push Bar: initiates mag cycle, frees up two hands for part handling and inspection

- Adjustable Tailstock facilitates movement back & forth on rail to accommodate various lengths of your test pieces

Features

- 6000 amp FW/HWDC and 5000 amp AC multidirectional output

- Multidirectional power supply — three phases: contacts,Flux-Flo™ coils and auxiliary coil

- Programmable Logic Controller (PLC) and Graphics Display Control Panel

- Large Illuminated Display with Digital Amperage Readout

- Three independent variable current controls with keypad entry

- Visual/Audible current assurance alarms with alarm log

- Modular digital solid state circuitry

- Quick disconnect wiring

- 50 customer programmable recipes

- Automatic piece parts counter

- Security systems (password protection, supervisor locks)

- Footswitch-operated pneumatic headstock

- Adjustable tailstock with crank

- Push bar

- Stainless steel tank

- Front and rear hardwood grilles

- Magnetization shot duration adjustment

Specifications

- Dimensions w/o hood 88 1/2"L x 41"W x 60 1/4"H (224.8 cm x 104.1 cm x 153 cm)

- Net weight 1900 lbs (861 kg)

- Coil diameter 16" (40.6 cm)

- Input 460 VAC, 50/60 Hz, three phase

- Line current 400 amperes

- Recommended line fuse 200 amperes

- Recommended wire size #2/0 AWG

- Duty cycle 0.5 seconds ON, 10 seconds OFF

- Part length capacity 41" (104.1 cm)

- Part weight capacity 1500 lbs (680 kg)w/optional steady rests

- Tank capacity 10 gallons (37.9 liters)

- Convenience outlets (1) 115 VAC, 5 amperes

- Air supply 60–100 psi (4.2–7.0 kg/cm2)

- PLC Modular Design

- Display screen size 9 1/2" (24.13 cm)

More information here ...