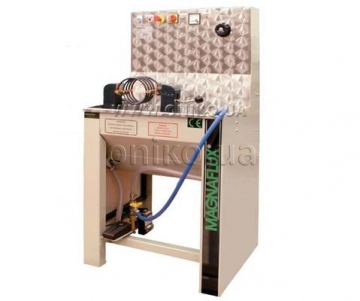

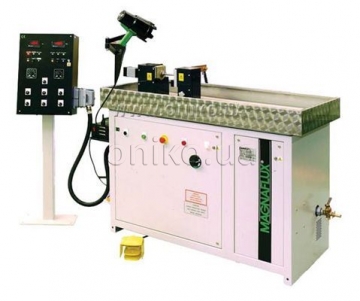

Stationary Flaw Series MAG-20

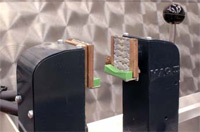

MAG 20 SERIES A light/medium duty machine designed for the inspection of ferrous components up to 550 mm in length

The Magnaflux MAG 20 is the ‘maid of all work’, in machine shops, tool rooms, foundries and similar plants where the low volume testing of ferrous components is required.

It is a basic, self contained, low cost unit which provides the perfect answer to locating fatigue cracks or processing defects by the “wet continuous” method of magnetic particle inspection.

As a standard unit it develops 1,000 amps AC current and features a fixed headstock, insulated 150mm coil, sliding tailstock with clamping mechanism, footswitch to initiate the current and a complete bath circulation system comprising of pump, agitator, hose and nozzle.

| Specification and Operating Data | |

|---|---|

| Magnetising Current Output | 1000 Amps A.C. R.M.S. |

| Coil Output | 4500 Ampere turns max. A.C. R.M.S. |

| Coil Size | 150 mm Internal Diameter |

| Maximum Component Length | 550 mm |

| Current Control | Infinitely Variable Non Sinusoidal |

| Typical Duty Cycle | 1.5 seconds ‘ON’ – 15 seconds ‘OFF’ |

| Main Electrical supply requirements | 220 or 240 volts, 50 Hz 1ph |

| Line current draw for duration of maximum current shot | 30 Amps |

| Recommended external fuse size | 20 Amps |

| Mains input cable size ( 15 metre maximum length) | 4.00mm2 |

| Tank Capacity | 18 Litres |

| Floor Area | 760mm x 915mm (with GD Hood) 760mm x 600mm (without Hood) |

More information here ...