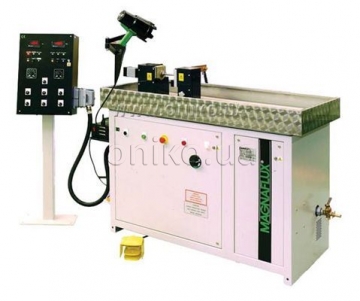

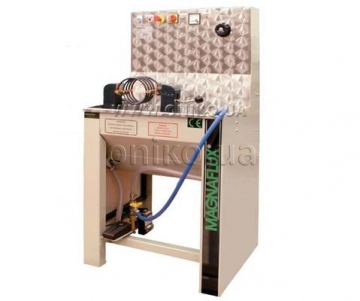

Stationary Flaw Series MAG-50

MAG 50 SERIES A range of heavy duty machines designed for the inspection of ferrous components up to 2.5 metre in length

Operating accessories

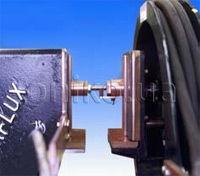

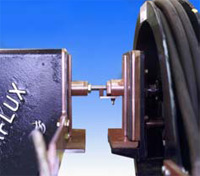

STEADY REST

The twin rollers of the steady rest allow rotation of components. It is fixed directly to the headstock.

AUXILIARY ADAPTORS

These auxiliary adaptors fit on to the head and tailstocks of the MAG50 bench units to assist in the handling of short/small parts.

STEADY REST

MAG50 Bench mounted twin roller steady rest allows rotation of components.

| Specification and Operating Data | |||

|---|---|---|---|

| Model Range | MAG 50/3H | MAG 50/5H | MAG50/6FR |

| Maximum Output Current | 3000 amps AC & Half Wave DC |

5000 amps AC & Half Wave DC |

6000 amps Full Wave DC |

| Line current draw for duration of maximum current shot | 170 amps | 270 amps | 110 amps |

| Recommend external fuse size | 80 A | 125 A | 50 A |

| Mains input cable size(30 metre maximum length) | 35 mm2 | 70 mm2 | 25 mm2 |

| Demagnetisation | Decaying AC | Reversing DC | |

| Typical Duty Cycle | 1.5 seconds ON; 15 seconds OFF | 1 second ON; 10 seconds OFF | |

| Mains Electrical. Supply requirements | 380 or 415 volts, 50 Hz 1ph | 380 or 415 volts, 50 Hz, 3 ph | |

| Current Control | Optional 300,400,500mm and 625mm | ||

| Compressed Air Line | Minimum 5 bar (customer to provide regulator) | ||

More information here ...