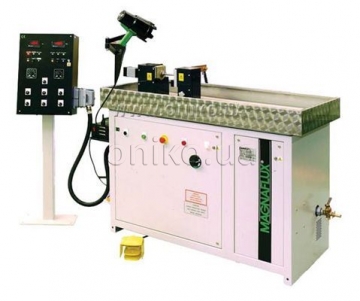

Stationary Flaw Series MAG-40

MAG 40 SERIES. A range of medium duty machines designed for the inspection of ferrous components up to 1.0 metre in length.

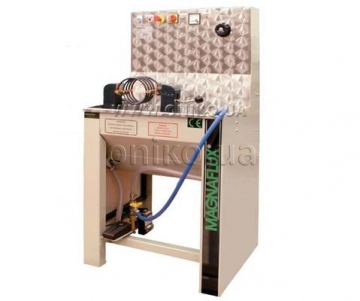

Magnetic Particle Inspection MAGNAFLUX MAG 40HD provides fast and high quality circular magnetization of ferromagnetic structures and parts up to 1 meter. If necessary control of very small parts can be clamping coil. Used in tool shops, workshops, foundries and other similar units, where you want to view details of medium size. MAGNAFLUX MAG 40HD provides identification of fatigue cracks and defects in the metal with "wet" method of magnetic particle control.

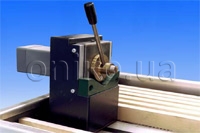

Magnetic Particle Inspection MAGNAFLUX MAG 40HFD provides fast and high quality circular magnetization of ferromagnetic structures and parts up to 1 meter. The patented design provides a longitudinal magnetization without using a transverse coil. If you need to monitor very small parts can be clamping coil. Used in tool shops, workshops, foundries and other similar industries, where required inspection of parts of medium size. MAGNAFLUX MAG 40HFD provides detection of fatigue cracks and defects in the metal with "wet" method of magnetic particle control.

| Specification and Operating Data | MAG-40 HD | MAG-40 HFD |

|---|---|---|

| Metering Digital | * | * |

| AC Current 2,500 amps RMS | * | * |

| H.W.D.C. Current 2,500 Magamps | * | * |

| D.C. Flux 20,000 ampre turn | * | |

| Auto Sequence | * | |

| Decay Demag Facility | * | * |

| Coil Diameter T = Traversing C = Clamping |

225mm (T) | 150mm (C) |

| Current Control | Infinitely Variable | |

| Typical Duty Cycle | 1.5 seconds ‘ON’ – 15 seconds ‘OFF’ | |

| Mains Electrical supply requirements | 380 or 415 volts,50 Hz, 1ph | |

| Line current for duration at maximum current shot | 63 amps | |

| Recommended external Fuse Size | 50 amp | |

| Mains input cable size (30 metre length maximum | 16 mm2 | |

| Compressed Air Line | Minimum 5 Bar (customer to provide regulator) | |

More information here ...