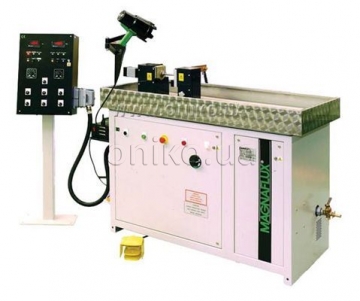

RXH 3520/48 Magnetic Particle Flaw Detection

RXH 3520/48 MAGNETISING FIXTURE Designed for the Magnetic Particle Detection of surface and sub-surface cracks and flaws in large crankshafts

The units are lathe-type in structural design, being built on a heavy duty hollow section framework and enclosed by steel panels having a wear-resistant “RAL 7032” paint finish.

Fitted in the top half of the framework is an inspection bath comprising a stainless steel V-shaped tank which contains the magnetic bath and agitation system. The head and tailstock are in an aluminium fabrication and provide positive clamping and direct electrical contact (circular magnetisation). The headstock is fixed top left of the unit and incorporates a pneumatically operated clamping plate and contact pad.

A similar contact pad is fitted to the tailstock which moves on a trackway extending the length of the unit. The tailstock adjustment is by means of a hand crank whilst the faceplate rotation is motor driven, the headstock faceplate has free rotation. Two heavy-duty movable steadyrests with adjustable height rollers are provided for component support and they sit directly onto the trackway (bedbar).

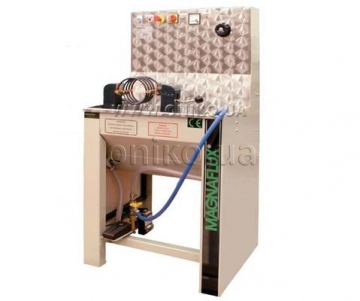

The magnetising powerpack is a separate mobile unit (MAG50/5HM) – see separate leaflet.

Specification and Operating Data

Maximum Component Size: 600 mm diameter x 4800 mm long

Maximum Component Weight: 2000 kg

Circular Magnetism: Pneumatic Clamping Faceplate

Longitudinal Magnetism: 625 mm Diameter Encircling Traversing Coil

Part Handling: Motorised Rotation

Demagnetisation: Decaying A.C.

Current Control: Infinitely Variable

Electrical Supply: 380/415V, 3-phase Neutral and Earth

Air Supply: 5 Bar (min)

More information here ...